Building with earthbags (sometimes called sandbags) is both old and new. Sandbags have long been used, particularly by the military, for creating strong, protective barriers, or for flood control. The same reasons that make them useful for these applications carry over to creating housing. Since the walls are so substantial, they resist all kinds of severe weather (or even bullets) and also stand up to natural calamities such as earthquakes and floods. They can be erected simply and quickly with readily available components, for very little money.

Earthbag building fills a unique niche in the quest for sustainable architecture. The bags can be filled with local, natural materials, which lowers the embodied energy commonly associated with the manufacture and transportation of building materials. The fill material is generally of mineral composition and is not subject to decomposition (even when damp), attractive to vermin, or burnable...in other word it is extremely durable. The fill material is generally completely non-toxic and will not offgas noxious fumes into the building.

Earthbags have the tremendous advantage of providing either thermal mass or insulation, depending on what the bags are filled with. When filled with soil they provide thermal mass, but when filled with lighter weight materials, such as crushed volcanic stone, perlite, vermiculite, or rice hulls, they provide insulation. The bags can even act as natural non-wicking, somewhat insulated foundations when they are filled with gravel.

Because the earthbags can be stacked in a wide variety of shapes, including domes, they have the potential to virtually eliminate the need for common tensile materials in the structure, especially the wood and steel often used for roofs. This not only saves more energy (and pollution), but also helps save our forests, which are increasingly necessary for sequestering carbon.

Another aspect of sustainability is found in the economy of this method. The fill material can be literally "dirt cheap," especially if on-site soil is used. The earthbags themselves can often be purchased as misprints or recycled grain sacks, but even when new are not particularly expensive. Burlap bags were traditionally used for this purpose, and they work fine but are subject to rot. Polypropylene bags have superior strength and durability, as long as they are kept away from too much sunlight. For permanent housing the bags should be covered with some kind of plaster for protection, but this plaster can also be earthen and not particularly costly.

The ease and simplicity of building with earthbags should also be mentioned, since there is much unskilled labor available around the world that can be tapped for using this technology. One person familiar with the basics of earthbag building can easily train others to assist in the erection of a building. This not only makes the process more affordable, but also more feasible in remote areas where many common building skills are not to be found.

Small Domes

This three-page how-to shows the steps used in building

Riceland, a 14' diameter earthbag/papercrete dome. This prototype dome could serve as a model for emergency shelters, cabins, studios, garden sheds, etc. It should work well in earthquake-prone areas and places subject to flooding, winds, and hurricanes. It could be used as quick housing for people made homeless by natural disasters.

One of the most practical structures on a small farmstead is a multi-purpose garden structure that can serve as a storage shed or cool pantry above ground, or as a root cellar or storm shelter below ground. You can build this

Low-Cost Multipurpose Minibuilding for about $300 using earthbag construction. This was written by Owen Geiger and is excerpted from

The Mother Earth News.

The Hermit's Dome

The Hermit's Dome I ran across a web site that advertised building emergency shelters out of sandbags. I was quite intrigued by the concept and decided to try to build one for myself. My daughter was not too enthused about the idea. She didn't think that an 81-year-old man with a bad back should take on that kind of task, although she knew it was no use to try talking me out of it.

We made a 9-foot 6-inch diameter flexible form rammed earth structure for meditation purposes. We call it

A Meditation Kiva, a hut, a dome, a wonder. We felt the deep connection to earth and people throughout history as we filled the bags and slapped on the staw and clay plaster. How peacefully meditative it was to work with this medium, without mechanization or complicated tools and sophisticated know-how!

Kaki Hunter and Doni Kiffmeyer describe how they built their

Honey House. The merits of "Flexible Form Rammed Earth" are in its use of cost-effective materials, simple construction methods and the durable resistance to the ravages of fires, hurricanes, flooding, termites and, as Nader Khalili has proven in Southern California, earthquakes.

The OM Dome

The OM Dome My inspiration for earthbag building was on the beach in Thailand. I was pondering the creation of a sound temple and looking for local building materials. While on the beach I watched fishermen fill used woven poly bags with sand and stack them into a retaining wall. Epiphany! I remembered a research paper I did in college on earthen building and Nader Khalili.

At Terrasante Village, in the fall of 2000, our first experiment with earth was a simple, partially subterranian adobe-in-a-bag (aka earthbag) 12 foot circular structure with interior ferrocement retaining wall below grade. We called this

EarthDome House. Material for the bag walls was excavated from the interior space and the walls were stuccoed with 1” chicken wire mesh for extra strength.

Featured are the

Earthbag Domes of Akio Inoue of Tenri University, Japan. He assisted building these on the university campus, at an earthquake site near Jamnagar, India, and in Entebe, Uganda. These domes are being considered for use as refugee shelters in the region, because they provide good protection from bullets, fire, wind, and rain.

Building an earthbag dome

Building an earthbag dome describes hows this 4 meter diameter dome was built at a sustainability education center in Australia. Some of the unique features integrated into the design of the dome include: a rubble trench footing containing a French drain, appropriate passive solar design, rammed earth flooring and a living roof.

Angel's Dome in Mexico

Angel's Dome in Mexico was built using volcanic stone as fill material, barrels as window forms, and has a small loft. There will be a skylight at the top, and the windows feature eyebrows. It has a nice curved buttress for the entryway.

A Little Dome in Durban, South Africa

A Little Dome in Durban, South Africa The boys really liked to learn, though some prefer to learn one aspect and then keep doing that. It seems that in each place only one or two have the mental makeup to really try to absorb everything from A to Z. The brothers who were building got more and more inspired when it was nearing completion and in the end we finished a early.

Four

Dome Cottages in Thailand would provide a better standard of acommodation for the volunteers. The training and building went well with so many people involved. A few had specially come to do the training and others from the Burmese refugee community were very keen to aquire these new skills. The children just had great fun and in the end a house to claim as built by them.

QUSAYR AL-JAWASREH, designed by Kikuma Wantanabe, is a

Community Center for the Al-Jawasreh Village, located in South Shounah near the Dead Sea in Jordan. It is a public facility open to the local community, where educational and vocational programs are provided.

New Zealand Hermitage

New Zealand Hermitage

We've decided to “start small” and build an earthbag

dome sauna. This will give us some practice with getting a feel for our sand-clay mixture and the amount of work involved in stuffing and laying our tubing. Our goal is to build a home for as little money as possible, and teach others to do the same. If you have played with clay, chances are you can build a dome.

The hut

The hut is 8' in diameter (wide enough to comfortably lay down inside) and stands over 7' high inside at the center. I used 200 bags for a total cost of less than $40. Building the hut was inexpensive, but required a lot of labor. As far as I'm concerned it has provided many hours of silent retreat for me and it was indeed a ... labor of love.

An earthbag

model dome is part of the ISEGERO village in Eastern Uganda. It is the beginning of the ecovillage in the Mpambo Afrikan Multiversity, started in August, 2009. The university aims towards Africa cultural revival. They are trying to construct an ecovollage made of earthbag in which the African culture is reflected. One small model dome was constructed to teach them about this technology.Complex Domes

Kelly and Rosana Hart's earthbag/papercrete home

Kelly and Rosana Hart's earthbag/papercrete home completed in 2000. This 1250 sq.ft. home was made with the earthbags filled with socria (crushed volcanic stone) and covered with papercrete plaster. The passive solar design performs well at over 8,000 ft. in the Colorado mountains.

This

Earthbag Clinic in the Philippines was coordinated by Illac Diaz, the young Phillipine visionary who has spearheaded many such earthbag projects in the area, including several schools. There is no text describing the process of building, but the many photos tell most of the story. You will notice that the bag material was removed after the fill had set up and before the building was plastered.

Featured are the

Earthbag Domes of Akio Inoue of Tenri University, Japan. He assisted building these on the university campus, at an earthquake site near Jamnagar, India, and in Entebe, Uganda. These domes are being considered for use as refugee shelters in the region, because they provide good protection from bullets, fire, wind, and rain.

Using a technique developed by Cal Earth in California, architect Nader Kahlili worked with

the Pegasus Children's Project to build a small sustainable village of over 40 “super adobe domes” to provide permanent shelter. This project accommodates 80 children, 10 staff, and a small school near Kathmandu, Nepal, in the Himalaya Mountains — the first of its kind for the region.

Hootenanny in Baja

Hootenanny in Baja Together with the earth, sun, and sea, we will craft an abode of beauty, simplicity and comfort. Working together, we'll expand our horizons - how to build a safe and beautiful home for a small cost. I made the project under time, a little over budget, and am significantly happier with the result than I had envisioned. So, I'm a happy man.

Uganda Ecovillage

Uganda Ecovillage. In 2008 Sunny Tsai volunteered to assist a team of two architects and eight professors, under the direction of Akio Inoue of Tenri University, Japan, to construct an ecovillage by Lake Victoria, Uganda, East Africa. This ecovillage was designed by architect Kikuma Watanabe of the Kochi University of Technology.

Jorge Dominguez has been helping his friend Mark Hanson build the first

Code Permitted Hawaiian Dome Home. This is a copy of a desert earthbag dome adapted to super heavy rain. It took Mark like a year to get his permit. Lots of patience required. This dome is going to be sold to a retired couple. It is not meant for a family with kids.

The

Joshua Tree Home is the eventual residence of Mark Reppert. It is a double eco dome designed by Cal-Earth. San Bernardino County gave Mark a permit to build the house. The building regulations there are some of the toughest in the country. We were an international crew of builders. There were 5 core builders with extra volunteers on occasion.

The

Warsaw Dome project was built in Poland as a demonstration of inexpensive, sustainable building techniques that others might employ. This is one of many such projects initiated by the Earth, Hands, and Houses organization founded by Paulina Wojciechowska, author of

Building with Earth: A Guide to Flexible-Form Earthbag Construction .

Two retaining walls and the beginning of an earthbag tube dome home in

Midpines, California. "Michele and Sara-Ann standing next to our first window form. We're fast approaching 3000 feet as of April 5, 2007."

HomeGrown HideAways, a natural building school in Kentucky helped John Capillo build his

Kentucky Dome Home while running a workshop to teach people the fundamentals of earthbag building. The code officials were incredibly open to new things and gave John his permit without hassle. His design has a 16 foot dome with a larger circle coming off the dome that has a wooden roof.

Krpasundarananda is a Meditation teacher with Ananda Marga and has been a Monk since 1991. The

Eco-Dome in Ananda Nagar, India is a showpiece to inspire other members and teachers and he hopes one or two of the laborers or visiting villagers get the idea and will want to learn more. He'll be happy to help them to build in their own villages.

Building the

Double Dome in Mongolia was fun and again I learned a lot. I thought I came to teach, but then found that I have hardly any experience how to work with a bunch of unruly teenage boys and girls, what to say...I didn't even speak the language! The kids are very proud of their work and the dome will be used for teenage programs.

Mickey Mouse in Morelia, Mexico

Mickey Mouse in Morelia, Mexico We should get sponsorship from Disney Land... Mickey Mouse is easy to recognise. Oops, they may charge us royalties.

The Sandbag Shelters of Nader Khalili

The Sandbag Shelters of Nader Khalili I will show you what to me, is an exellent way to made architecture, how we can make, with few and natural resources, great space design, and at the same time, solve differents social problems, one of the principal motives and preocupations of modern architecture.

Tim Hall's Earthbag Home in Hawaii

Tim Hall's Earthbag Home in Hawaii shows, mostly in pictures, how a CalEarth-style Superadobe home was built, using cement-stabilized tubular bags that were then burned away before the building was plastered.

Just east of Bisbee, Arizona this

Ransom Ranch Dome project was completed after studying and admiring Nader Khalili's alternative building work since 1985. I finally apprenticed with him at Cal-Earth in November 2007.

This

Dome Experiment with Large Windows has a 24' inside diameter at the base, rising on a ‘catenary' curvature to sloping truncation around 16' above grade. This was attempted as a fairly aggressive exploration of structural potential with this system in several capacities, and quite cognizantly surrendered to the tests of time. I can only stand behind this as an artist of sorts, as it is beyond most established protocol of construction.Vertical Wall Homes

Baraka's House

Baraka's House evolved after she asked me to help her design her custom earthbag home. She had very specific ideas about the shape and room arrangement, but wanted some input as to what was practical with earthbags and how to accomplish many details of construction. She also wanted a passive solar design and wanted my my advice about this as well.

This tastefully designed home was built on a shoestring budget by owner/builder

Alison Kennedy in Moab, Utah. The 1,000 square foot earthbag home is the first permitted earthbag house in Utah. Alison in-filled earthbags between concrete and wood posts. A concrete block bond beam was mortared into place on top of the wall. Described by Kaki Hunter and Doni Kiffmeyer.

Steve and Carol Escott built a two story home on the remote island of Rum Cay, Bahamas, assisted by Kaki Hunter and Doni Kiffmeyer. This

Sand Castle features a first floor made with earthbags filled with sand and crushed coral, upon which a second story, framed house would be constructed and covered with a hip-style roof.

Robin's House

Robin's House built near San Miguel de Allende in Mexico is based on a traditional Southwestern adobe and has an open floor plan.

Theo describes the building of

The Sun House in Haiti. "Rice, barley, wheat all come in poly bags which we've saved. They will be used to hold a mix of moistened sand and clay. The bags will be laid out much like bricks or blocks and barbed wire will be used as mortar between the rows."

We spent a year intensively researching alternatives to mainstream building techniques and settled on a plan that fit our very small budget, was simple and low tech, that two reasonably fit persons could build alone. We chose to build a

Buddhist Hermitage, which will be the primary residence for the hermitage staff. After months of design work the dome shape was rejected, in favor of sqaure corners and straight walls to accomodate living spaces inside.

Several

Eternally Solar Earthbag Projects in South Africa demonstrate a unique approach that features poly bags that have been partitioned into three compartments lengthwise, so that the two outer compartments can be filled with soil while the central compartment is left unfilled and creates a void to insulated the center of the wall.

Project in Belize

Project in Belize This project is presented primarily as a photo essay, but the wealth of details makes it nearly self-explanitory. Kaki Hunter and Doni Kiffmeyer, the authors of

Earthbag Building are present, and their trademark methods are employed.

Tatu Penrith's Sandbag Hideaway

Tatu Penrith's Sandbag Hideaway is a haven on top of the world and an appealing terracotta and green house with thick walls that give it an earthy, handmade look. 'Sandbags are much cheaper than bricks, as well as being warm in winter and cool in summer. You can use unskilled labour; we used the women from Sir Lowry's Village down the road, and they sang while they packed the bags.'

The Gypsy Farm Adventure

The Gypsy Farm Adventure chronicles several years in the life of the Newberry family while they build a hybrid earthbag, cob, strawbale, pole frame, ferrocement home in Georgia. "I will continue this journey we once called a Newberry adventure, yet today I see this small adventure as part of a greater journey with it's connections to the others on this planet as we travel together."

La Casa de Tierra

La Casa de Tierra is a rental house located in Ojochal, also called Playa Tortuga (Turtle Beach), on the Southern Pacific coast in Costa Rica.

Judy and her son live on the island of

Dominica. They are working to build a earthbag home for Judy. The idea of an earthbag home is that it is resistant to extreme climate occurrences such as hurricanes and tornadoes. It is also supposed to be able to handle earthquakes. Judy hopes to be prepared to deal with whatever challenges come her way.History

by Kelly Hart

The idea of making walls by stacking bags of sand or earth has been around for at least a century. Originally sand bags were used for flood control and military bunkers because they are easy to transport to where they need to be used, fast to assemble, inexpensive, and effective at their task of warding off both water and bullets.

At first natural materials such as burlap were used to manufacture the bags; more recently woven polypropylene has become the preferred material because of its superior strength. The burlap will actually last a bit longer if subjected to sunlight, but it will eventually rot if left damp, whereas polypropylene is unaffected by moisture.

Because of this history of military and flood control, the use of sandbags has generally been associated with the construction of temporary structures or barriers. Using sandbags to actually build houses or permanent structures has been a relatively recent innovation.

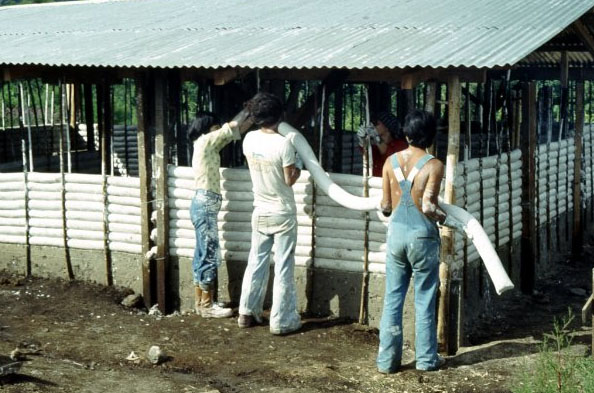

In 1976 Gernot Minke at the Research Laboratory for Experimental Building at Kassel Polytechnic College in Germany began to investigate the question of how natural building materials like sand and gravel could be used for building houses without the necessity of using binders. The use of fabric-packed bulk material was found to be a cost-efficient approach. They used pumice to pack in the bags, because it weighs less and has better thermal insulating properties than ordinary sand and gravel. Their first successful experiments were with corbelled dome shapes ( an inverted catenary) which was obtained with the aid of a rotating vertical template mounted at the center of the structure.

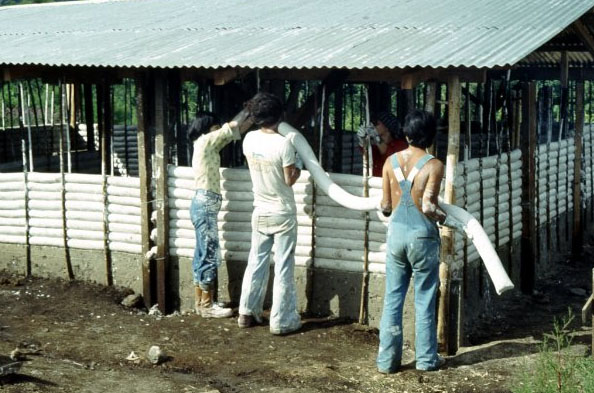

1978, a prototype house using an earthquake-proof stacked-bag type of construction was built in Guatemala. They used cotton bags soaked in lime-wash to protect the material from rot and insects. When flattened, the bags measured roughly 8 X 10 cm. Vertical bamboo poles placed on both sides of the bags and interconnected with wire loops gave the stacked bags stability. The bamboo rods were fixed to the foundation and to the horizontal tie beam at the top. (See

this page for more about this.)

It was an Iranian-born architect named Nader Khalili who has popularized the notion of building permanent structures with bags filled with earthen materials. Actually his first concept was to fill the bags with moon dust! Attending a 1984 NASA symposium for brainstorming ways to build shelters on the moon, Khalili coupled the old sandbag idea with the ancient adobe dome and arch construction methods from his homeland in the Middle East. He realized that bags filled with lunar “dirt” could be stacked into domes or vaults to provide shelter.

Khalili came up with a further refinement on this building concept on Earth: for a more permanent, shock-resistant structure, why not place strands of barbed wire between the courses of bags, thus unifying the shell into a more monolithic structure?

At first Khalili was filling his experimental bags with desert sand, but then he evolved his idea of “superadobe,” where bags or long tubes of polypropylene bag material would be filled with a moistened adobe soil that would dry into large adobe blocks. In this case the original bag material was merely the initial form and would not necessarily be an integral part of the eventual structure.

Soon after these first experiments, Khalili began publicizing his work through newspaper and magazine articles and conducting workshops and seminars on the techniques that he was perfecting. Many people who read about his work, visited his compound in Hesperia , California , or studied with him there, decided to go ahead with their own experiments with his ideas.

Among these “early adopters” were Joe Kennedy, Paulina Wojziekowska, Kaki Hunter and Doni Kiffmeyer, Akio Inoue, and Kelly Hart. I believe that it was Joe Kennedy who coined the more general term “earthbag” to suggest that the bag could contain a variety of earthen materials.

Paulina Wojciechowska was the first to write an entire book on the topic of earthbag building: Building with Earth: A Guide to Flexible-Form Earthbag Construction was published in 2001. This featured some of her early experiments done at Khalili's CalEarth, along with several other case histories.

Akio Inoue, from Tenri University in Japan, has done extensive experimentation with earthbag construction, both on the campus of the University and in India and Africa where many other domes have been built for assistance programs.

Kaki Hunter and Doni Kiffmeyer (a couple) became enamored with earthbag construction after studying with Khalili, and worked on a variety of projects, both for themselves and for clients. In 2004 they wrote and got published another book, Earthbag Building : the Tools, Tricks and Techniques , based on their particular experience.

Kelly Hart (the author of this article) first began experimenting with earthbag building in 1997, after being exposed to the concept while producing his video program, A Sampler of Alternative Homes: Approaching Sustainable Architecture . He later documented his experience in actually building his own home in another program titled Building with Bags: How We Made Our Experimental Earthbag/Papercrete Home . Both of these programs are now available as DVD's.

In the meantime, Nader Khalili was continuing the promotion of his “Superadobe” technique and eventually decided to patent the idea, which he obtained in the U. S. in 1999, using very general terms that cover using bags made of any material being filled with virtually any material, and combining these with barbed wired between the courses. While having made many public statements that this concept was his gift to humanity, he obviously wanted to capitalize on the potential economic reward.

Many of us who had been engaged in promoting earthbag building on our own were contacted by Khalili and asked to enter into contracts with him in order to continue our work. It didn't take much research to discover that his patent could easily be disqualified because he had been publicizing his techniques through various media for at least four years before he even applied for his patent. Patent law clearly states that such publicity occurring prior to one year before the patent application would disqualify it for consideration.

So now the door is wide open for anyone to take this concept and run with it, and more people are doing so all the time, all over the world. While Khalili (and most of his students) have focused primarily on using the bags to form large adobe blocks, others have tried filling the bags with a variety of other materials, such as crushed volcanic rock, crushed coral, non-adobe soils, gravel, and rice hulls.

Earthbag building is unique among all other building technologies in that it can be either insulation or thermal mass, depending on what the bags are filled with. This is a very important distinction, because these characteristics of a wall greatly influence how comfortable, economical, and ecological any given system will be.

Safety is of prime concern with all building technologies, and much experimentation and testing has been done to establish guidelines for many ways of building. Khalili has established a relationship with the building department in Hesperia , California where CalEarth is located, an area where earthquakes are naturally a great danger. In 1993 live-load tests to simulate seismic, snow and wind loads were performed on a number of domed earthbag structures at CalEarth and these exceeded code requirements by 200%.

In 1995 dynamic and static load tests were performed on several prototypes for a planned Hesperia Museum and Nature Center to be constructed using Khalili's Superadobe concepts with both dome and vault shapes. All of these tests exceeded ICBO and City of Hesperia requirements.

In 2006, at the request of Dr. Owen Geiger of the Geiger Research Institute of Sustainable Building, the Department of Civil and Mechanical Engineering of the U.S. Military Academy at West Point conducted several controlled and computer-monitored tests to determine the ability of polypropylene earthbags filled with sand, local soil, and rubble to withstand vertical loads. Their written report concluded that “overall, the earthbags show promise as a low cost building alternative. Very cheap, and easy to construct, they have proven durable under loads that will be seen in a single story residential home. More testing should prove the reliability and usefulness of earthbags.”

Despite the success of these tests, earthbag building concepts have yet to be incorporated into the International Residential Building Code. Obviously more enlightened acceptance of the demonstrated viability of earthbag building needs to occur!

It is difficult to know how many residences and other earthbag structures have been made at this point, probably hundreds if not thousands. Many of us have been promoting the technique for use as emergency shelters, and certainly some have been built for this reason. It is easy for folks to accept this way of building temporary shelters because it fits the historical model of sandbag use.

But many of us have also built substantial homes using earthbags, and in the process realized how truly versatile and sustainable the technique is. I wouldn't be surprised if many of these earthbag homes are still standing long after their conventional counterparts built contemporaneously have disintegrated.

Earthbag building fills a unique niche in the quest for sustainable architecture. The bags can be filled with local, natural materials, which lowers the embodied energy commonly associated with the manufacture and transportation of building materials. The fill material is generally of mineral composition and is not subject to decomposition (even when damp), attractive to vermin, or burnable...in other word it is extremely durable. The fill material is generally completely non-toxic and will not offgas noxious fumes into the building.

Earthbag building fills a unique niche in the quest for sustainable architecture. The bags can be filled with local, natural materials, which lowers the embodied energy commonly associated with the manufacture and transportation of building materials. The fill material is generally of mineral composition and is not subject to decomposition (even when damp), attractive to vermin, or burnable...in other word it is extremely durable. The fill material is generally completely non-toxic and will not offgas noxious fumes into the building. Earthbags have the tremendous advantage of providing either thermal mass or insulation, depending on what the bags are filled with. When filled with soil they provide thermal mass, but when filled with lighter weight materials, such as crushed volcanic stone, perlite, vermiculite, or rice hulls, they provide insulation. The bags can even act as natural non-wicking, somewhat insulated foundations when they are filled with gravel.

Earthbags have the tremendous advantage of providing either thermal mass or insulation, depending on what the bags are filled with. When filled with soil they provide thermal mass, but when filled with lighter weight materials, such as crushed volcanic stone, perlite, vermiculite, or rice hulls, they provide insulation. The bags can even act as natural non-wicking, somewhat insulated foundations when they are filled with gravel.  Because the earthbags can be stacked in a wide variety of shapes, including domes, they have the potential to virtually eliminate the need for common tensile materials in the structure, especially the wood and steel often used for roofs. This not only saves more energy (and pollution), but also helps save our forests, which are increasingly necessary for sequestering carbon.

Because the earthbags can be stacked in a wide variety of shapes, including domes, they have the potential to virtually eliminate the need for common tensile materials in the structure, especially the wood and steel often used for roofs. This not only saves more energy (and pollution), but also helps save our forests, which are increasingly necessary for sequestering carbon. Another aspect of sustainability is found in the economy of this method. The fill material can be literally "dirt cheap," especially if on-site soil is used. The earthbags themselves can often be purchased as misprints or recycled grain sacks, but even when new are not particularly expensive. Burlap bags were traditionally used for this purpose, and they work fine but are subject to rot. Polypropylene bags have superior strength and durability, as long as they are kept away from too much sunlight. For permanent housing the bags should be covered with some kind of plaster for protection, but this plaster can also be earthen and not particularly costly.

Another aspect of sustainability is found in the economy of this method. The fill material can be literally "dirt cheap," especially if on-site soil is used. The earthbags themselves can often be purchased as misprints or recycled grain sacks, but even when new are not particularly expensive. Burlap bags were traditionally used for this purpose, and they work fine but are subject to rot. Polypropylene bags have superior strength and durability, as long as they are kept away from too much sunlight. For permanent housing the bags should be covered with some kind of plaster for protection, but this plaster can also be earthen and not particularly costly.  The ease and simplicity of building with earthbags should also be mentioned, since there is much unskilled labor available around the world that can be tapped for using this technology. One person familiar with the basics of earthbag building can easily train others to assist in the erection of a building. This not only makes the process more affordable, but also more feasible in remote areas where many common building skills are not to be found.

The ease and simplicity of building with earthbags should also be mentioned, since there is much unskilled labor available around the world that can be tapped for using this technology. One person familiar with the basics of earthbag building can easily train others to assist in the erection of a building. This not only makes the process more affordable, but also more feasible in remote areas where many common building skills are not to be found.

Uganda Ecovillage

Uganda Ecovillage

The

The

The Sandbag Shelters of Nader Khalili

The Sandbag Shelters of Nader Khalili Tim Hall's Earthbag Home in Hawaii

Tim Hall's Earthbag Home in Hawaii

Project in Belize

Project in Belize  Tatu Penrith's Sandbag Hideaway

Tatu Penrith's Sandbag Hideaway The Gypsy Farm Adventure

The Gypsy Farm Adventure La Casa de Tierra

La Casa de Tierra

It was an Iranian-born architect named Nader Khalili who has popularized the notion of building permanent structures with bags filled with earthen materials. Actually his first concept was to fill the bags with moon dust! Attending a 1984 NASA symposium for brainstorming ways to build shelters on the moon, Khalili coupled the old sandbag idea with the ancient adobe dome and arch construction methods from his homeland in the Middle East. He realized that bags filled with lunar “dirt” could be stacked into domes or vaults to provide shelter.

It was an Iranian-born architect named Nader Khalili who has popularized the notion of building permanent structures with bags filled with earthen materials. Actually his first concept was to fill the bags with moon dust! Attending a 1984 NASA symposium for brainstorming ways to build shelters on the moon, Khalili coupled the old sandbag idea with the ancient adobe dome and arch construction methods from his homeland in the Middle East. He realized that bags filled with lunar “dirt” could be stacked into domes or vaults to provide shelter.  At first Khalili was filling his experimental bags with desert sand, but then he evolved his idea of “superadobe,” where bags or long tubes of polypropylene bag material would be filled with a moistened adobe soil that would dry into large adobe blocks. In this case the original bag material was merely the initial form and would not necessarily be an integral part of the eventual structure.

At first Khalili was filling his experimental bags with desert sand, but then he evolved his idea of “superadobe,” where bags or long tubes of polypropylene bag material would be filled with a moistened adobe soil that would dry into large adobe blocks. In this case the original bag material was merely the initial form and would not necessarily be an integral part of the eventual structure.